WELCOME TO THE SURFACE MODELLING

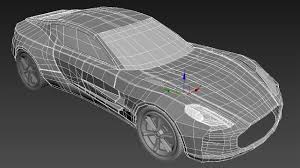

The process or method involved in representing solid objects is called surface modelling. This process converts different 3D modelling types. That means converts the 3D object to show procedural surfaces, identifies imperfections, and applies smoothness. Using surface modelling architectural illustrations and 3D animations can be created.

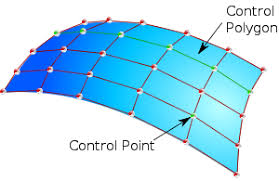

The pros and cons of surface modelling are as follows. Surface modelling focuses on the external aspects of an object. It develops an object by stretching the surface on it with 3D curves which are created by the designer. The surface boundaries of the object are well described. The viewer can see the surface point where the solid interior is located. Surface modelling is useful for the external appearance of the product or the design.

FROM OUR GALLERY

REACH US WITH SURFACE MODELLING SERVICE.

The free form shapes and sleek design can be possible but the feature of watertight is lacking because the cut design becomes hollow. Also, it is hard to go back and make changes while any design is developed using surface modelling as they are not parametric. The changes in a specific area do not create updating over the whole design.

There are various surface modelling techniques available which are surface patch, coons patch, bicubic patch, B-Spline surface. The usage of technique depends on the surface representation like sculpture or building blocks or polygon or Nurbs etc.

The surface modelling gives you the capability to build a visual representation of an object’s or design’s exterior and its contours or surface. The objects can be mechanical components or complex organic shapes or imported solid or reference geometry or hybrid designs. Using surface modelling, the changes to an imported model can be made, more complex shapes can be designed, between faces, fillet or draft can be created.

The computer-aided design applications for displaying solid appearing objects using a mathematical method is surface modelling. The users can view the specific object from different angles. It has a wide range of applications in consumer products, marine vehicles automobile panels, aircraft structures, etc.